Schmelzen, Warmhalten und Gießen von Metallen

Effizient und ressourcenschonend mit Induktions-Technologie

Bei der induktiven Erwärmung von Metallen wird das Material in einem elektromagnetischen Feld direkt erhitzt – ohne den Umweg über die Verbrennung von Gas oder Öl.

Mit der Entscheidung für die Induktions-Technologie leisten unsere Kunden einen wichtigen Beitrag für die Einsparung fossiler Energieträger, die Reduzierung von CO2-Emissionen und insgesamt zur Transformation der Metallindustrie. Wenn die Anlagen mit grünem Strom betrieben werden, arbeiten sie sogar vollkommen CO2-frei.

Hinzu kommt, dass viele Induktionsöfen Schrott schmelzen und so Metalle in einem beständigen Kreislauf halten – ein überzeugendes Beispiel für die Wiederverwendung wertvoller Ressourcen in der „Circular Economy“.

Mit breitem Ingenieurwissen, jahrzehntelanger praktischer Erfahrung und hoher Innovationskraft zählt Induga beim induktiven Schmelzen und Gießen von Metallen weltweit zu den Technologieführern.

Unsere Anlagen im Überblick

Filter - Anwendungen

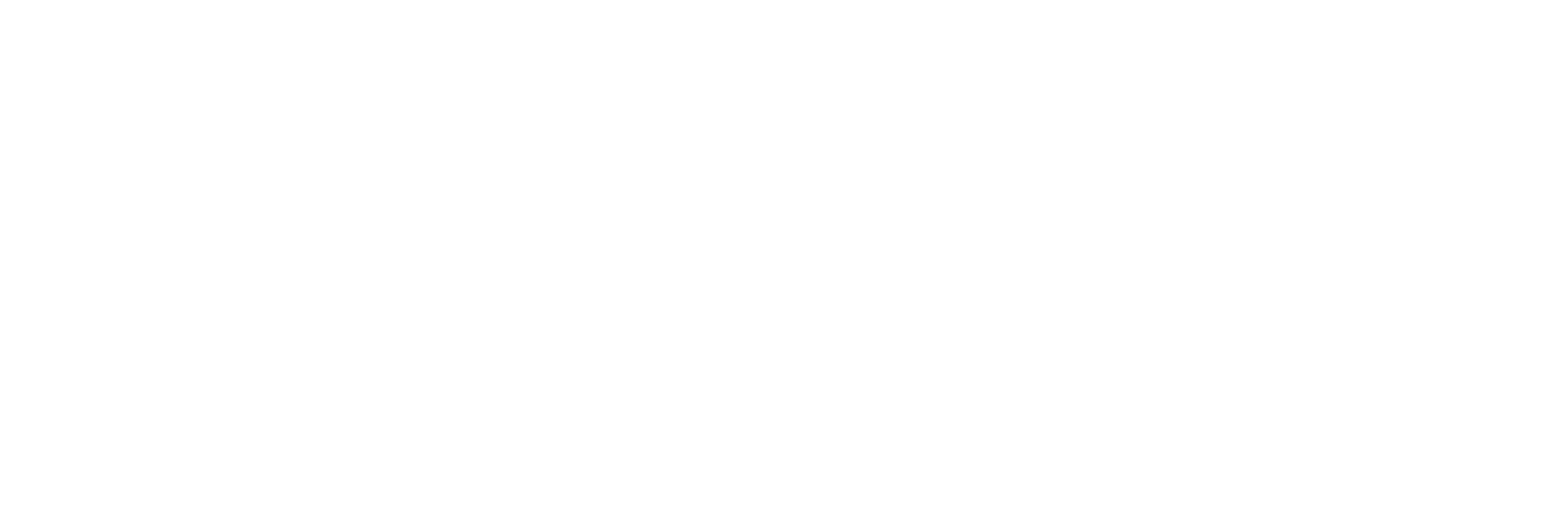

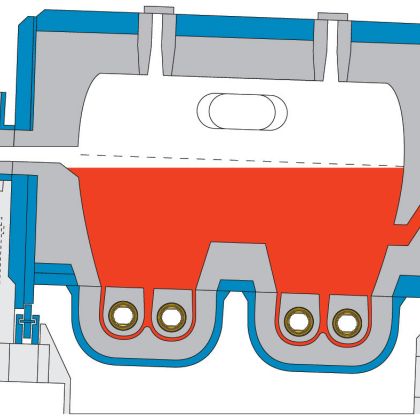

Form- und Seriengießanlage PUMA

Automatisches, unbeheiztes Kipppfannen-Gießsystem, mit hoher Dosiergenauigkeit für Formanlagen im Serienguss

mehr erfahren

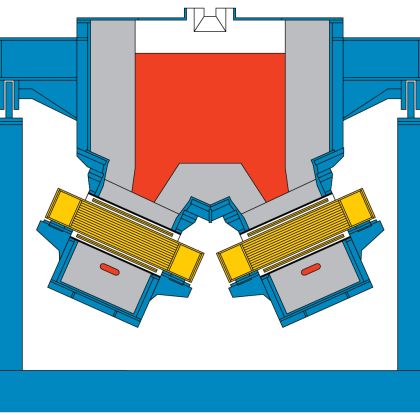

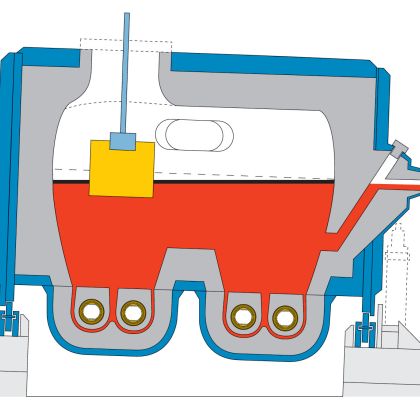

Rinnenschmelzöfen

Induktionsöfen mit einem Oberofengefäß, das von Rinneninduktoren beheizt wird

mehr erfahren

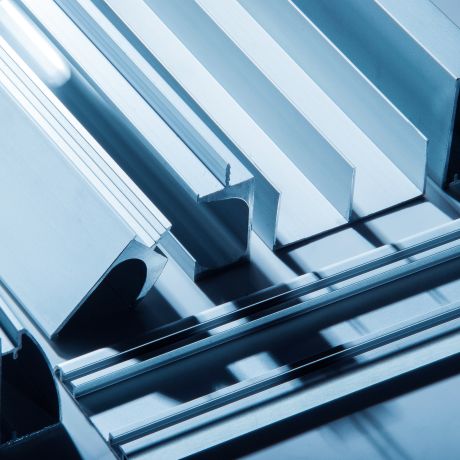

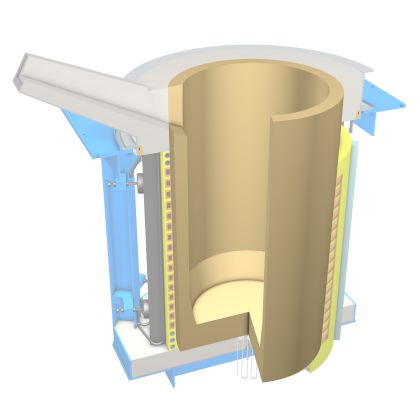

Tiegelschmelzöfen

Zylindrische Induktionsöfen, deren Tiegel von einer Spule umfasst wird

mehr erfahren

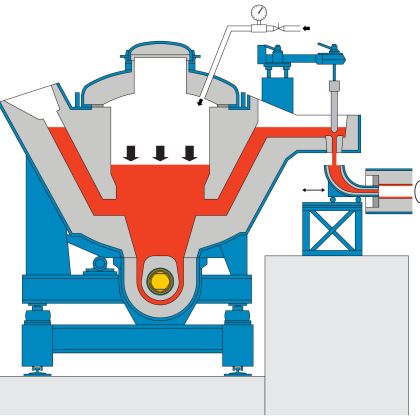

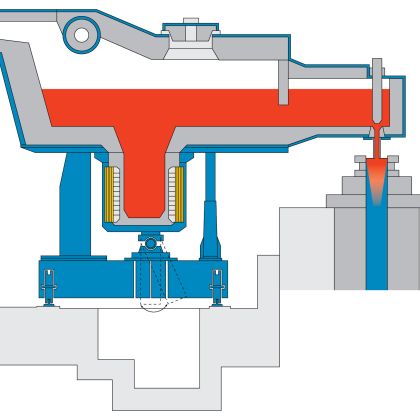

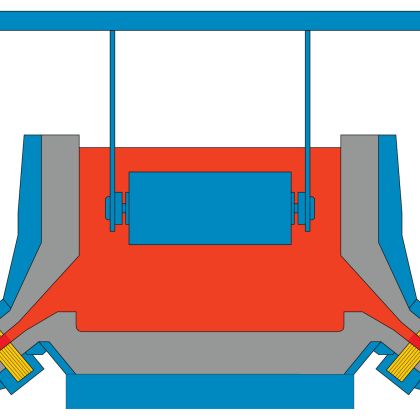

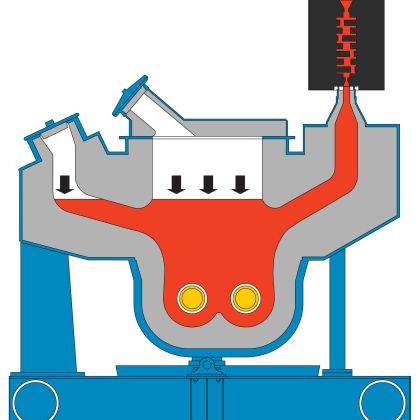

Niederdruck-Gießanlagen

Druckbeaufschlagte Induktionsöfen, aus denen eine Form oberhalb gefüllt wird

mehr erfahren

Vertikal-Stranggießöfen

Kippbare Gießöfen mit Rinnen- oder Tiegelinduktor und einem Vorherd für das Gießen in einen vertikalen Strang

mehr erfahren

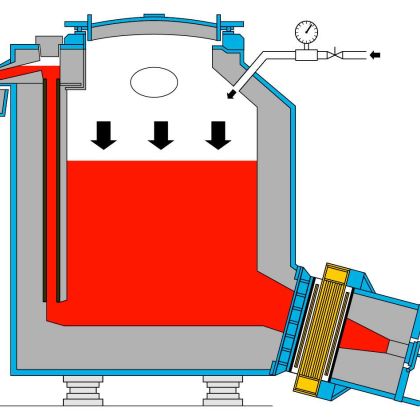

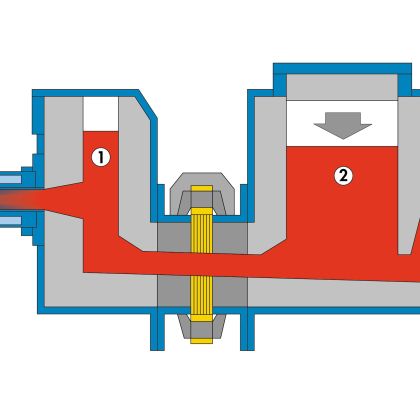

Horizontal-Stranggießöfen

Ofengefäß mit einem Rinneninduktor, an den eine horizontale Stranggießkokille angeflanscht wird

mehr erfahren

Trommelöfen

Trommelförmiger Induktionsofen für Kupfer, meist verwendet für OF Kupfer mit der Möglichkeit der Sauerstoffreduktion

mehr erfahren

Bandbeschichtungskessel

Rinnenbeheizter Induktionsofen als rechteckiger Beschichtungspott für Stahlbänder

mehr erfahren

Stückbeschichtungskessel

Induktionsofen als Beschichtungspott für das Tauchbeschichten von Stückgut

mehr erfahren

Vorschmelzer

Rinnen- oder Tiegelöfen, die die Schmelze beim Verzinken direkt in den Beschichtungspott überführen

mehr erfahren

Kathodenschmelzer

Wannenförmiger Ofen mit bis zu sechs Induktoren für das Schmelzen von Zinkanaoden

mehr erfahren

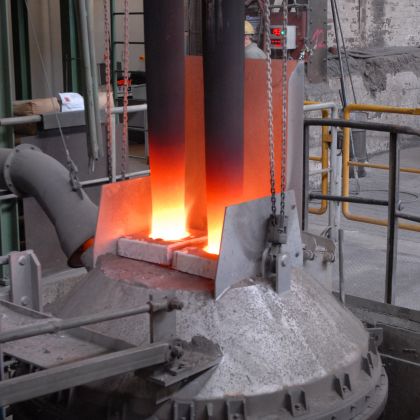

Plasma-Technologie

Plasmabrenner für das Beheizen der Pfanne oder des Tundish beim Stranggießen von Stahl

mehr erfahren

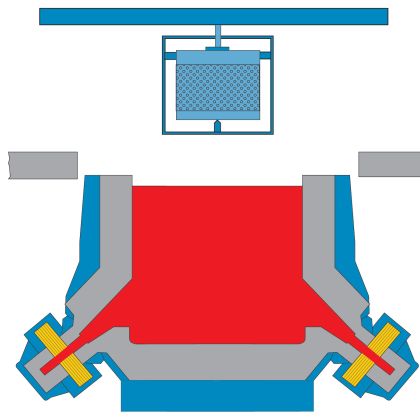

Niederdruck-Gießanlagen im Sandguss

Druckbeaufschlagte Induktionsöfen, aus denen eine Sandform oberhalb gefüllt wird

mehr erfahren

Werden Sie Teil

Unseres Teams

OTTO JUNKER gilt als einer der größten Arbeitgeber der Nordeifel!

Etwa 680 Mitarbeiterinnen und Mitarbeiter, einige von Ihnen in der dritten Generation, sind bereits Teil der OTTO JUNKER Gruppe.

Werden auch Sie Teil des Teams!

Anrufen +49 2473 601-710

+49 2473 601-710

Schreiben info@induga.de

info@induga.de